Our R&D system covers four categories:

Technological R&D: The core objective is to break through the underlying technological bottlenecks in the field of precision injection molding and seize the initiative for future development. R&D focuses on novel molding technologies (such as micro-foaming, process optimization for liquid silicone molding), digital tools (simulation accuracy improvement, intelligent in-mold pressure detection algorithms), etc. These efforts not only directly enhance the efficiency of project R&D and product development but also enable us to anticipate industry technology trends (such as lightweight and intelligent molding) and provide a technical foundation for other R&D efforts.

Project R&D: Taking specific projects as the carrier, focusing on the systematic development of precision injection molded components, with the core goal of enhancing product performance indicators. For example, for automotive precision components, medical high-precision parts, etc., by optimizing structural design and integrating multi-functional modules, the added value of products is improved.

Process R&D: Continuously optimize the production process, with the core focus on addressing pain points in mass production, improving manufacturing efficiency, reducing costs, or enhancing product quality.

Product development: We intervene in the product lifecycle in sync with our customers, participating from the conceptual design stage. Through digital verification, we transform customer needs into feasible mold and part solutions.

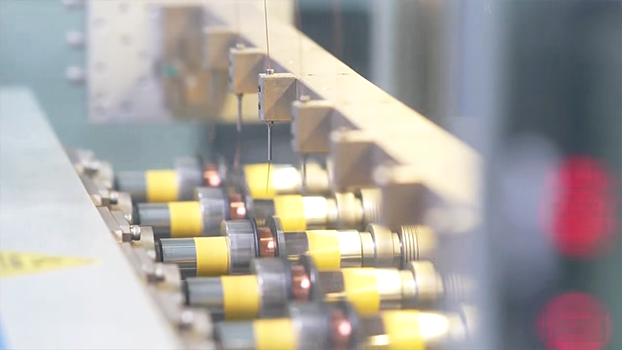

Production:

The company possesses core process capabilities such as coil winding, stamping, liquid silicone, micro-foaming, embedding, and coating, as well as automated assembly capabilities. It can cover the entire process from the manufacturing of key components (such as coils), multi-cavity and multi-type product molding, to high-precision subsequent assembly through automated equipment, achieving integrated delivery from core component processing to finished product automated assembly.

Relying on standardized management models, the company focuses on efficiency improvement and cost optimization. With professional processes, automation technology, and scientific control, it efficiently meets the diverse needs of customers in coil winding, product production, automated assembly, and other aspects. This not only ensures coil accuracy, molding quality, and assembly stability, but also provides more comprehensive, economical, and efficient solutions for the upstream and downstream of the industry chain.

0512-51917787

0512-51917787 WeChat Official Platform

WeChat Official Platform

WeChat Channels

WeChat Channels